Shanghai Xukun specializes in high-precision sheet metal auto parts for a wide range of automotive applications. From car chassis components to engine brackets and body panels, our custom stamped and formed parts are built to exacting tolerances. We use advanced die-making, CNC machining, and automated stamping processes to ensure dimensional accuracy, repeatability, and cost-efficiency.

We focus on manufacturing superior-top quality Car or truck Rear Wheel Moulds at Kaihua Mold. Our automotive molds are made for optimum performance and light-weight, lessening cycle time and manufacturing fees when improving merchandise accuracy and eradicating sink marks. By minimizing clamping power and product or service weight, our molds enable you to reach top-quality outcomes with considerably less effort and value.

OEM parts are sometimes costlier than aftermarket parts, as These are produced to exacting standards and are made to the particular prerequisites of a specific vehicle. This means that they are generally of larger good quality and present a much better suit than aftermarket parts.

Let Elimold, a firm with around twenty decades of encounter in mold making, Develop your custom automotive plastic injection mold. Our various capabilities and in depth manufacturing and testing products are perfect for sophisticated injection mold building Work opportunities. The gear we use to help make custom injection molds involves a number of CNC machining facilities with 5-axis capabilities.

3D printing generally is a Expense-effective choice to 1-off prototypes mainly because it eliminates the need for costly tooling, therefore reducing manufacturing fees. It provides design liberty and can be a practical alternative to creating automotive prototypes.

Many Offshore mold makers Slice corners in the course of trials, treating them for a formality to obtain the mold permitted and delivered. This technique typically causes complications later on.

Insert molding is definitely an impressive injection molding approach that will involve inserting a metal section right into a mold before the act of injection molding. With This method, you might get rid of the need for more parts and form a single ingredient instead.

Our absolutely integrated State-of-the-art Resource High quality Planning (APQP) growth system is supported by cross-purposeful groups which have the proper mixture of know-how to be sure A prosperous start of each automotive mold job.

As well as OEM automotive enterprise, we have a robust fascination and functionality from the automotive aftermarket sector.

We assistance you in co-building polymer parts that meet up with your software specifications for cheapest leakage, minimal friction, large velocity and exact in shape. Our substance authorities will see the appropriate materials.

SLM 3D printing may also be used to manufacture certain end-use automotive parts. SLM 3D printing is able of manufacturing intricate and large-top quality parts. SLS 3D printing can be utilized to manufacture parts including bumpers, trims, and windbreakers that are usually injection molded.

While this prototyping approach normally takes for a longer period than 3D printing, it is more efficient in manufacturing significant parts.

Using these certifications, our customers can often be confident that Elimold will deliver them with the absolute best in services and good quality management. Our prime priority is usually to continuously fulfill the quality requirements of our customers. Elimold appreciates the exertions and ongoing help of high quality administration from its workers, internal auditors and stakeholders.

Additive producing Automotive Mold Manufacturer technological know-how could extend into a wider selection of injection molded automotive parts from the around potential. This may entail using technologies like selective laser melting (SLM) for doorways and physique panels and electron beam melting (EBM) for powertrain and drivetrain components.

Mentioned under are a few common materials Employed in die casting. Echofast does properly in making motor parts fabricated from aluminum.

Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Joseph Mazzello Then & Now!

Joseph Mazzello Then & Now! Macaulay Culkin Then & Now!

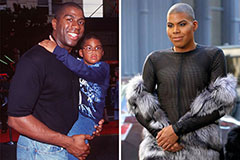

Macaulay Culkin Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now!